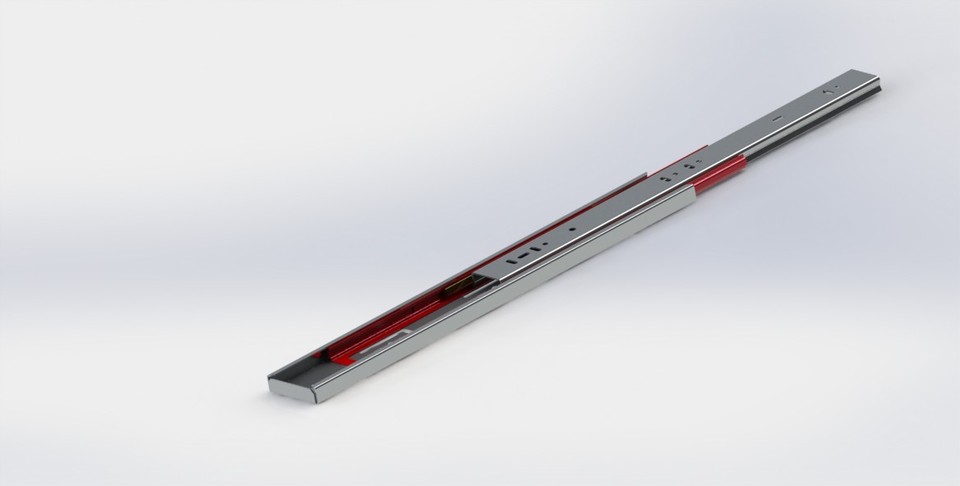

Desk drawers, filing cabinets, and other light-duty applications commonly use light steel draw slides. Pairs of linear bearings can also be utilized to sustain a moment load, however, this normally necessitates a larger bearing system. Telescopic führungsschiene provide the designer with a compact, high-load, and smooth-running option when your application requires precision, heavy loads, and/or continuous movement.

- Movements of the doors

- Arms for telescopic presses

- Extracting products

- Retrieval systems

- Any application that necessitates extraction, enlargement, relocation, or extension.

Telescopic rails are made of cold-drawn carbon steel with hardened raceways on the majority of models. Even when carrying rated loads at full extension, the robust design maintains stiffness and low deflections. Lighter slides deflect, causing the load to fall to one end and a difference in the force required to shift the weight. Even when vibrations, impacts, or shock loads are present, the quality construction of telescopic führungsschiene ensures steady movement. Telescopic outperform traditional draw slides in extreme applications, bearing heavier loads and having a longer service life.

Important benefits of telescopic rail

- For precise action and high-quality machinery feel, use smooth, accurate movement.

- For chemical, wet area, or caustic washdown conditions, corrosion protection options included nickel-coated rails and chrome-plated or SS ball bearings.

- For high load or long stroke applications, strokes up to 2m and loads up to 900kg are available.

- Low friction reduces the need for a drive motor and the amount of effort required by the user. You may either save money on drive components or give your equipment a higher-quality feel.

- Long service life with less maintenance, less downtime, and more production.

- For faster machine cycle times, precision construction permits speeds of up to 0.8m/s.

- Temperatures up to 130 degrees Celsius for a range of conditions, and up to 170 degrees Celsius with high-temperature lubrication.